Goal

- To learn more how engine/motor performance is measured

- Create a basic cheap dynamometer for home project use

Current Design

Components/Sub Assemblies

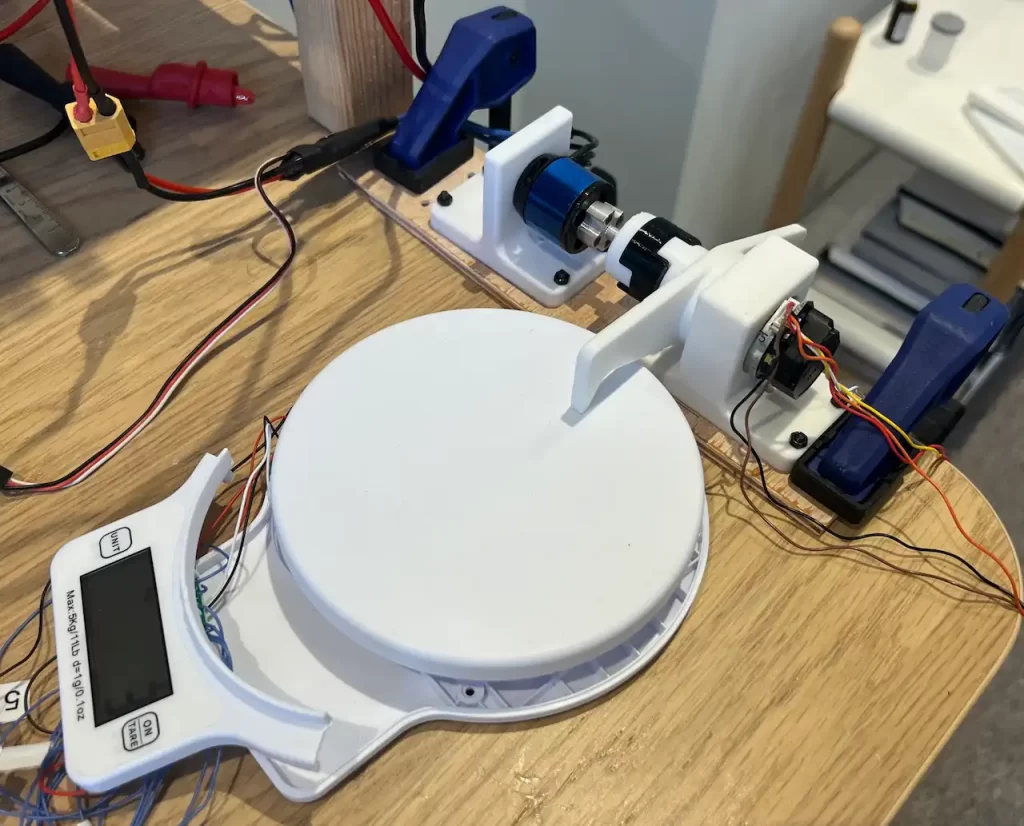

The dynamometer is currently made up of the following:

- A Feather 32u4 uSD Adalogger with 128×32 OLED Featherwing Display Module – Allows for a quick and simple interface and control of the ESC

- Electronic Speed Controller (ESC) – This is specifically for the BLDC motor under test, and will need to change dependent on the motor’s needs.

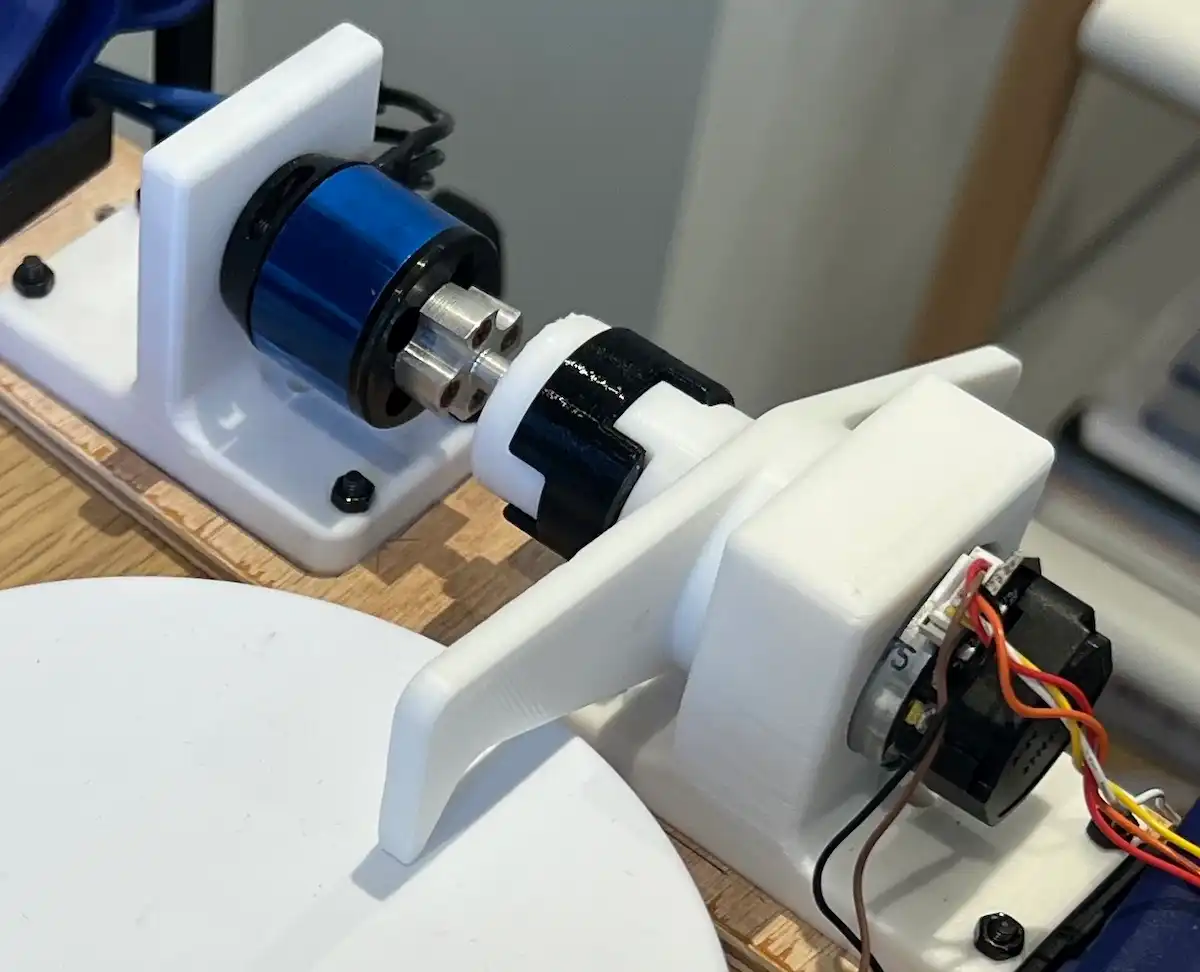

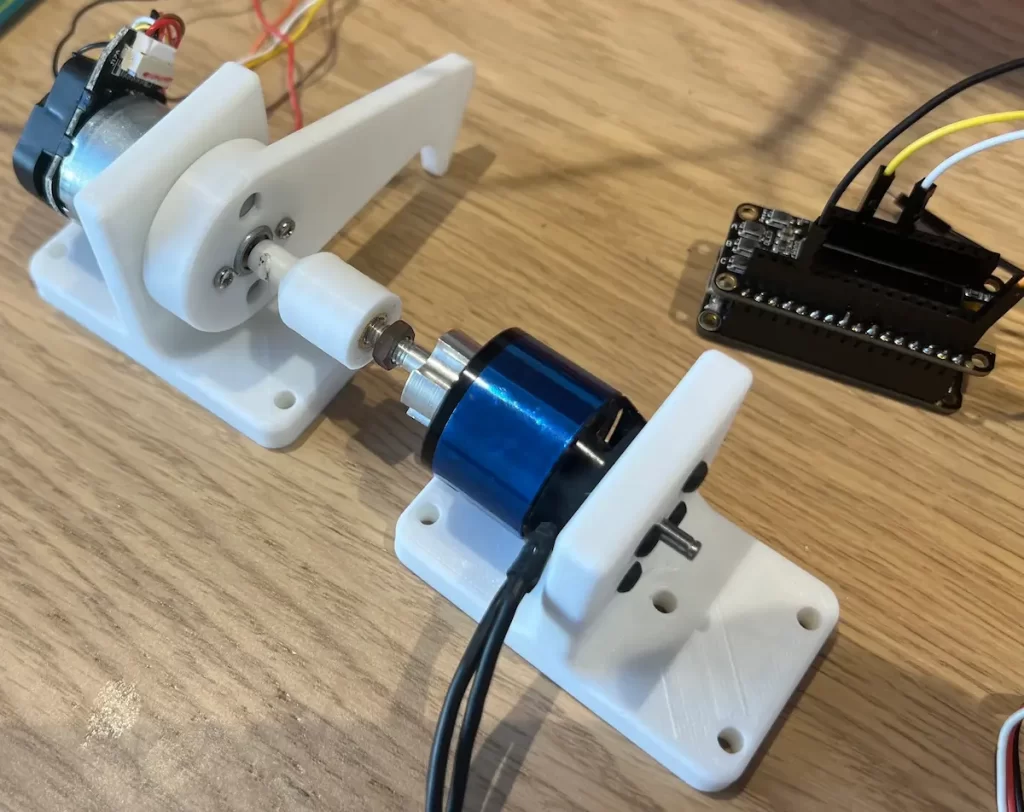

- Housings

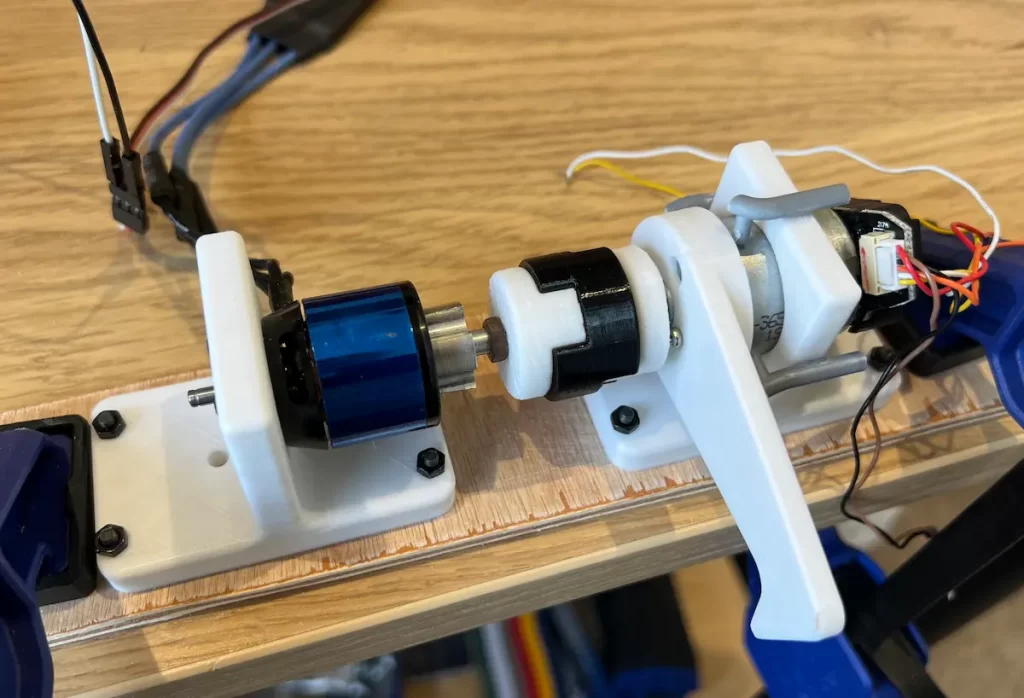

- Coupling – A TPU connection between the test and brake motors

- A Brake Motor – Provides a variable load and an arm to engage the load cell

- External Power Supplies – For the Feather board and motors.

What Performance It Measures

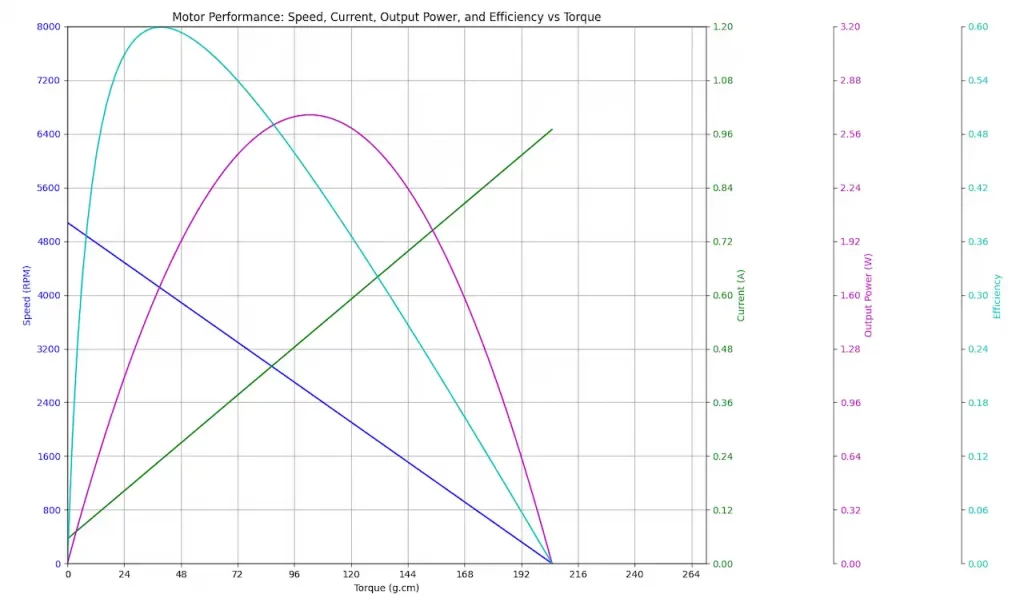

A motor has several different parameters that define it’s operating point and performance.

The common items provided, for a set voltage, by manufacturers include:

- Current, I (A)

- Output Power, P (W)

- Torque, T (Nm)

- Efficiency, n (%)

- Speed, (rpm)

Typically this is represented on a graph with Torque on the x-axis and everything else on the y-axis.

An example of a motor’s performance curves.

How it Measures

The principle of operation is as follows:

- An operation voltage is chosen (and ESC speed if applicable)

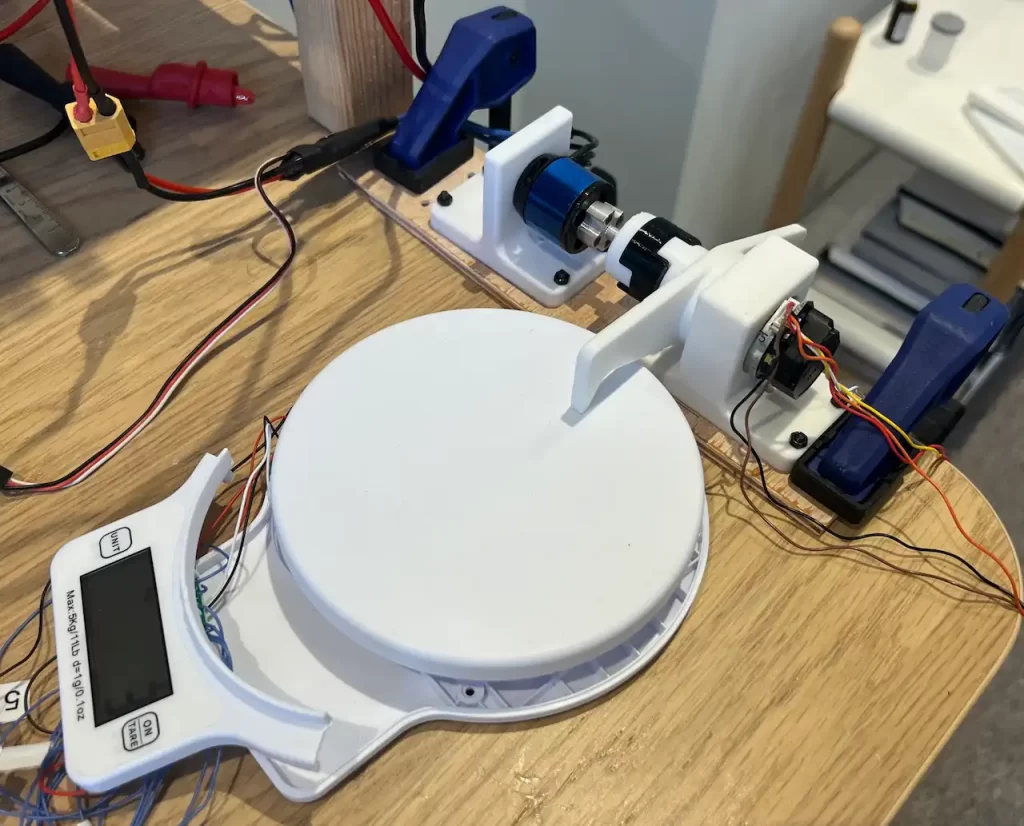

- The equipment is set up as in the picture below, including the motor to test.

- The brake motor provides a variable load for the motor under test

- With the test motor running the load applied by the brake motor is increased

- At various points recordings of measurements are noted for:

- Current

- Force on the load cell

- Speed

- Once you’ve swept the brake motor from no load on the test motor to zero rotations (ideally) the test can be stopped.

- The force on the load cell needs converting to Torque, with Output Power and Efficiency calculated from the measured values.

Video of the system running.

Future iteration ideas/intent

The current setup needs more to become a “usable tool” in my workshop.

Some of the current ideas and thinking I have for upgrades are:

- Integration with power supply

- Connect to my RS Pro power supply and automatically log the voltage and current linking with the other readings.

- To integrate this I need to understand what the ports and protocols are capable of communicating and designing how hardware and firmware can be added to incorporate this.

- Integration with the load cell

- Eliminate user steps and auto read the values for logging.

- An approach to coordinate with the displays clocked signals needs to be figured out.

Possibly using the displays row signals to drive interrupts (see the post for more info).

- Integration with speed sensor from the brake motor

- The brake motor includes a PCBA that is able to measure rotational speed.

Leveraging this directly would simplify work needed to get these values, or be used as a leaping point for my own design.

- The brake motor includes a PCBA that is able to measure rotational speed.

- A computer interface

- Being able to plug into the dynamometer with USB

- A simple GUI that can be used to

- start/stop logging

- drive the ESC

- drive the brake

- generate plots and tables of results

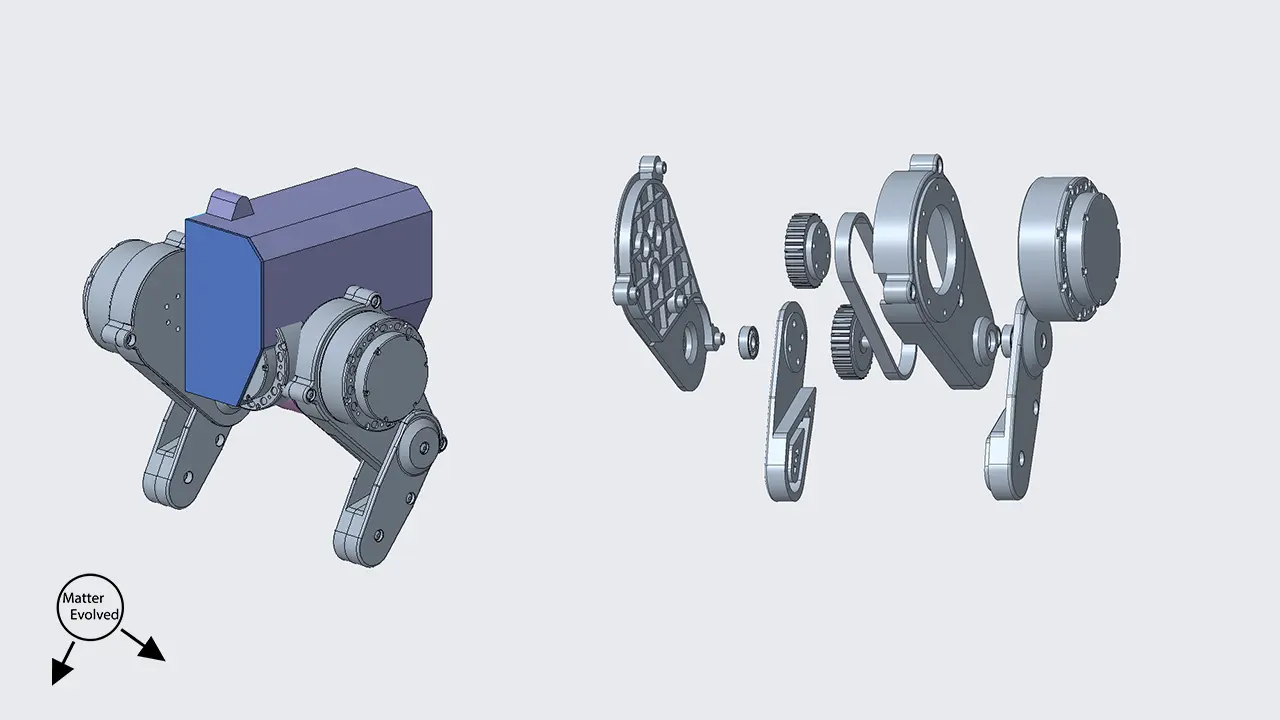

Reaching The Current Design

Initial design inspiration came from Jeremy Fielding‘s video of his dynamometer setup: How to Measure Horse Power for Any Electric Motor

Some Versions Made

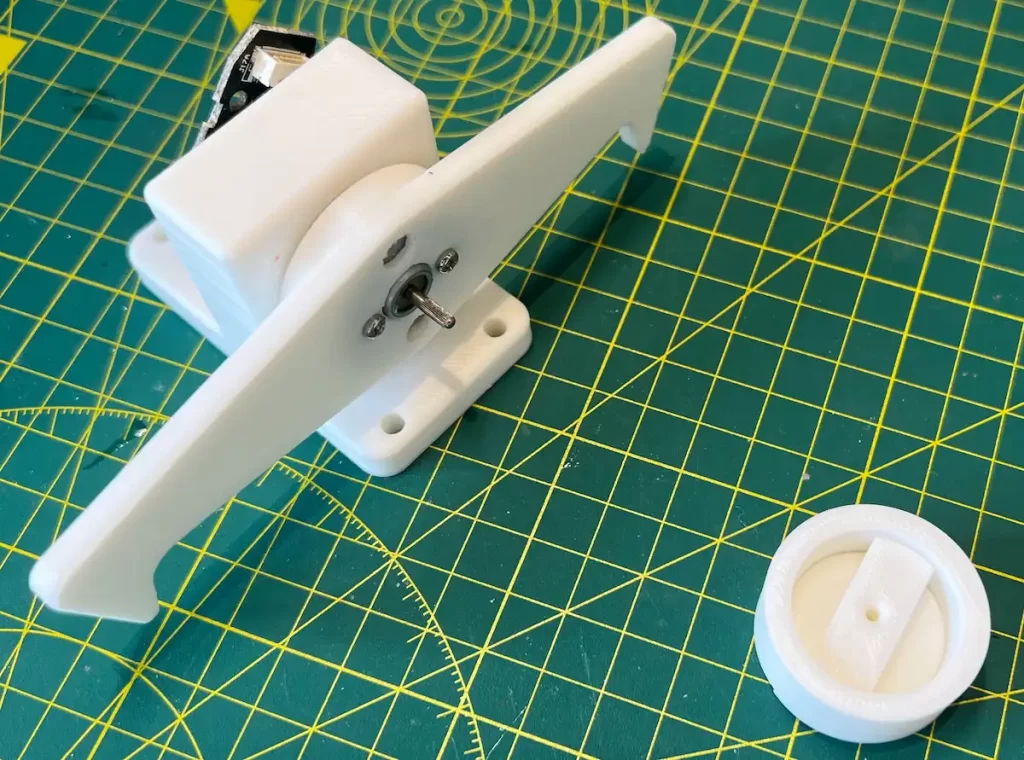

Housings

- Initial support for the brake motor was too thin.

It allowed lots of movement and vibrations as the motor could effectively pivot on the walls of the supports.- I glued on some plastic sprue I had, this helped a little but not enough

- The main improvement was thickening up the wall so the motor was more limited to:

- Roll around the axis

- Lateral movement along the axis

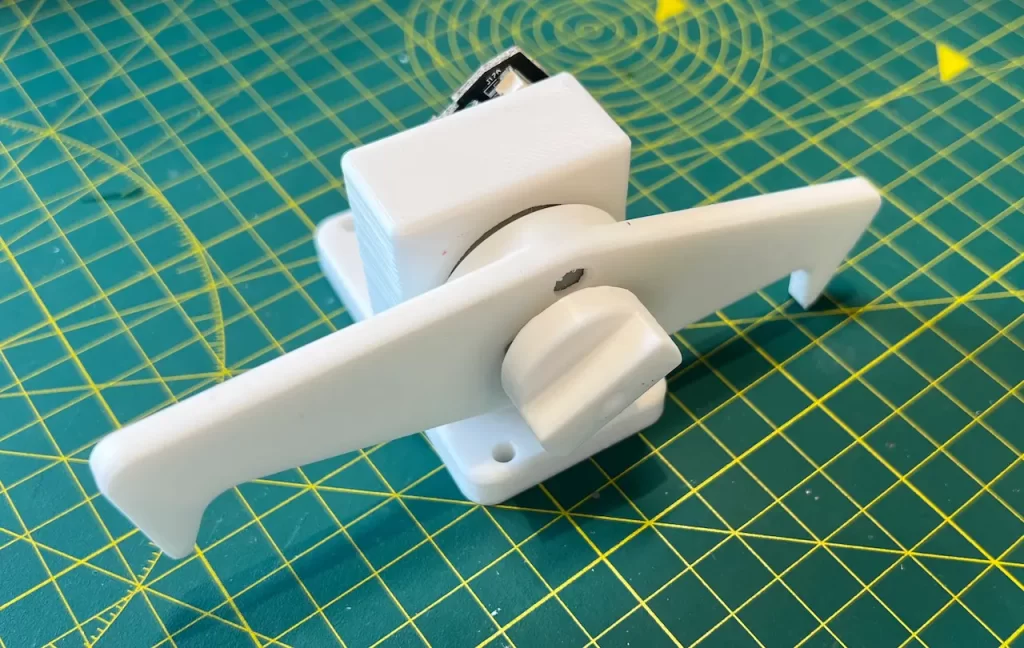

Coupling

- Initial designs and assembly approach were poor

- The couplings were very rigid which which contributed to lots of vibrations

- Assembly was hard to get good mounting and alignment

- Threaded inserts became offset to the axis

- Press fits became angled to the axis

- Changes made

- The coupling between the test and brake motors material was changed to TPU. This was the main reduction in noise and vibration

- An alignment jig was made for assembly, simple but super effective,

Was just a printed tube that restricted the angle the coupling could be when pressed onto the shaft.

Lever arm

- Single side to dual side

- Simple change, was already printing other parts so why not

- Allowed more flexibility on load cell placement

Load cell

Intent was to use a cheap set of hacked kitchen scales to provide the required force measurements.

This development is captured in a separate post here.

Until next time.